「ナノ物質のモノづくり」

弊社は、「ナノ物質のモノづくり」をビジネステーマに掲げ、基材表面にナノ材料の機能を付与する加工技術を手掛けています。具体的には、①あらゆる物質をナノサイズにする細分化技術(インク化技術)、②機能性インクを用いて基材表面に成膜・パターニングを行うプロセス技術、③機能を発現するための後処理技術を取り扱っています。

多くの案件を手掛けた経験・ノウハウを背景に、お客様のアイデアを実現するための原理検証(試作)から、機能性インクの開発や製品プロセスの構築まで、ご要望に沿った技術支援を行っております。その他、特定領域の特許・技術調査も承っております。

遠慮なく、ご相談をいただければ幸いです。ご要望あれば、WEBミーティングも承っております。

お知らせ

April 12, 2024平素は格別のお引き立てを頂き、誠にありがとうございます。 誠に勝手ながら、2024年4月27日(土)~5月5日(日)までの間、弊社はゴールデンウィークにつき休業とさせて頂きます。 休業期...December 22, 2023株式会社 樫の木製作所(埼玉県越谷市川柳町1丁目1番地3号、代表:大隈航大)と浜松ナノテクノロジー株式会社は、単層カーボンナノチューブに関する商品販売委託契約を締結いたしました。今後、樫の木製作...December 19, 2023平素は格別のお引き立てをいただき厚くお礼申し上げます。 誠に勝手ながら2023年12月28日(木)~2024年1月7日(日)を冬期休業とさせていただきます。 休業期間中のお問合せ...展示会情報

December 1, 20232024年1月31日(水)〜2月2日(金)に開催されるNanotech2024(東京ビッグサイト)に出展いたします。弊社ブースは、東4ホールの加工:ナノファブリケーションゾーン 4K-21 です...January 9, 20232023年2月1日(水)〜3日(金)10:00~17:00 東京ビッグサイト東1ホール ブース番号: 1J-05 ナノ材料の電子顕微鏡観察を容易にする「サンプルプレパレーショ...December 2, 20222022年11月29日〜12月2日に虎ノ門ヒルズで開催された「イノベーションリーダーズサミット2022」に参加しました。 代表取締役の川上友則が 11分野のビッグトレンド交流会(化学/材料...製品の紹介

画像クリックで関連ページへジャンプします。

化学合成、超音波ホモジナイザ、レーザアブレーション、ボールミリングなどによるナノ粒子の製造を手掛けています。お客様の要望に応じたナノ分散液(ナノインク)を試作いたします。

また、製品として純金属(Au, Ag, Pt, Pd)、金属酸化物(TiO2, WO3)、及びカーボン材料(SWCNT、金属的SWCNT、半導体的SWCNT、MWCNT、フラーレンC60C70)なども販売しています。ご用命のナノ材料がありましたら、お気軽にお問い合わせください。

応用例:

● 導電性インク

● 絶縁性インク

● 顔料インク

● 蛍光インク

● 触媒インク

● 酸化物インク

● 半導体インク

● グラファイトインク

● 単層カーボンナノチューブ(SWCNT)

● 金属的SWCNT

● 半導体的SWCNT

● 多層カーボンナノチューブ(MWCNT)

●フラーレンC60、C70

● 遮熱材料

● 断熱材料

● 抗菌材料

● 光触媒など

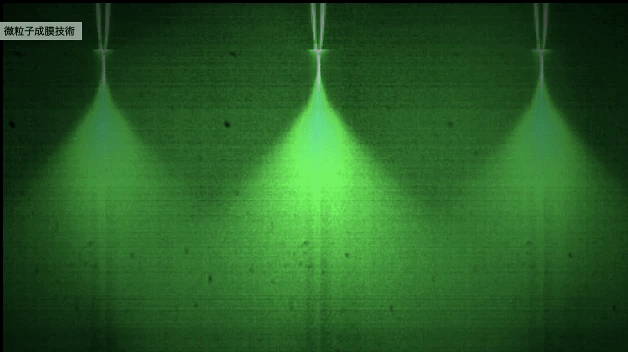

高品質の静電スプレーを用いて、ナノ粒子や液材料をワーク上に薄膜形成いたします。マスクを用いれば、パターン形成も容易にできます。

その他、ナノ粒子の分散塗布にも利用でき、電子顕微鏡(SEM、TEM)や原子間力顕微鏡(AFM)などで、一つ一つのナノ粒子に対する大きさ・形状を観察する際に役立ちます。応用例:

● 電子顕微鏡の観察試料の作製

● 機能性フィルムの製造

● 化学センサーの製造

● 燃料電池の電極・セパレータの製造

● 2次電池電極の製造

● 発光面の製造

● 質量分析のマトリックス塗布

●触媒ナノ粒子を用いた無電解メッキ

● 合金・複合材料の製造

● バイオセンサーの製造

● 表面増強ラマン基板の製造

● レジスト材の薄膜塗布

● レンズの反射率改善

● コンデンサーの製造

● EMI・EMS対策

● 微粉体の製造など

● 半導体ウエハ表面のコーティング

● 半導体ウエハ表面の模擬ダストの付着など

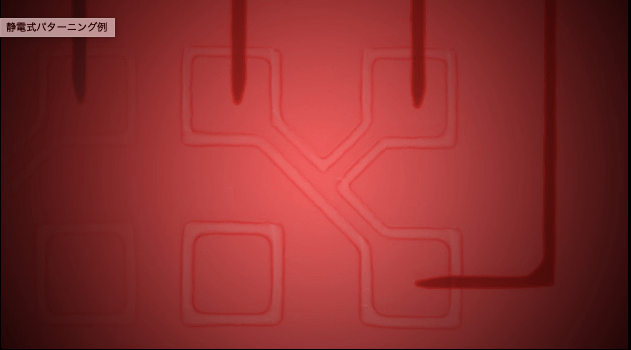

静電分注とは、静電吸引力を利用して、ノズルから微量のサンプル液を吐出する技術です。静電インクジェットと呼ばれることもあります。ナノインクや樹脂などの高粘性材料(5Pa・s以下を推奨)においても、nL, pL, fLオーダーで液滴形成ができます。また、ドット径で2μmφ以上、ライン線幅で10μm以上の描画を実現できます。機能性材料を用い、ワークの特定位置にドット・細線からなるパターンを直描したい用途で役立ちます。

応用例:

● プリンタブルエレクトロニクス

(3Dも含む)

● 配線のリペア

● 化学センサーの製造

● 小部品の樹脂封じ

● 局所電気絶縁性の付与

● 3Dデバイスの試作

●機能性パターンの試作

● ナノ粒子を用いた局所の無電解メッキ

● レジスト材の局所塗布

● バイオチップの製造

● 発光面、発電面の補助配線

● レンズの遮光部形成

● 受信アンテナの製造

● 生体組織の局所に試薬塗布

● ナノワイヤの製造

● ドット模様の形成など

新卒者採用情報

2024年度の新卒者募集中

先端材料に関わる仕事に興味ある方はご連絡ください!

応募要項をご説明いたします。

キャリア採用

先端材料に関わる仕事に興味ある方はご連絡ください!

会社概要

名称 浜松ナノテクノロジー株式会社

Hamamatsu Nano Technology Inc.

設立 2008年7月14日(現在第16期目)

所在地

〒433-8112

静岡県浜松市中央区初生町1384番地

TEL:053-522-9447

FAX:053-522-9448

資本金 2500万円

代表取締役 社長 川上友則(工学博士)

主要営業品目

①ナノ材料・ナノインクの開発、製造、販売、試作、委託生産

②静電噴霧成膜技術を用いた試作、受託加工、専用装置の開発、製造、販売

③静電分注・パターニング技術(静電インクジェット)を用いた試作、受託加工、専用装置の開発、製造、販売

④ナノ材料、製造プロセスに関する技術コンサルタント

⑤特定領域の特許・論文等の技術調査

取引銀行

静岡銀行

関係先

浜松ホトニクス株式会社

賛助会員

静電気学会

NBCI(ナノテクノロジービジネス推進協議会)

一般会員

日本化学会

フラーレン、ナノチューブ、グラフェン学会

代表取締役 社長 川上友則

お問い合わせ

弊社の製品・技術に関するお問い合わせを受け付けております。

技術に関する質問、カタログ請求、見積依頼等のご要望を記載ください。

WEBミーティングも承っております。

その場合は日程調整のやりとりをさせていただきます。

なお、問い合わせ内容に関する機密事項は厳守いたします。